We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

In aerospace, there’s no room for guesswork. Every component—no matter how small—must meet the highest standards. That’s why AS9100 exists. It’s the gold standard for quality management in aerospace manufacturing, created to ensure parts are built with precision, tested for reliability, and fully traceable at every step.

However, this certification isn’t just for planes and satellites. The same systems that keep aircraft safe are now guiding how many teams build parts for energy, medical, defense, and communications. And for components like transformers, inductors, and magnetic assemblies—where performance depends on exact design and materials—that kind of structure makes a real difference.

This post breaks down what AS9100 certification really involves, how it applies to magnetics, and why working with an AS9100-certified manufacturer is a smart move—even if you’re not building for aerospace. Whether your system operates at high altitudes or deep in a control cabinet, quality still matters.

AS9100 is a quality management standard created specifically for aerospace and defense. It’s built on ISO 9001 but adds deeper requirements that reflect the complex needs of flight systems. For custom magnetics manufacturers, it means every step of the process—from design to testing—is held to some of the highest standards in the industry.

AS9100 covers areas like:

Full traceability of materials

Detailed documentation for every step

Risk-based decision-making during development

Strict testing and verification processes

Oversight of suppliers to prevent issues with quality or counterfeits

Getting certified isn’t easy. It involves a full audit by an accredited body, along with proof that processes are stable and consistent. Not all manufacturers meet these standards.

Once certified, companies don’t stop there. AS9100 requires yearly audits and full recertification every three years. That ongoing process helps ensure manufacturers stay focused on improvement—not just passing a one-time check.

Magnetics often fly under the radar—until something goes wrong. But components like transformers and inductors are critical in nearly every system that depends on clean, stable power. When these parts fail, the results can be serious.

In aerospace, even a small shift in performance can affect everything from flight control to communication. Magnetic components must survive vibration, extreme temperatures, and sometimes radiation, all while maintaining their exact performance specs.

That’s where AS9100 makes a difference. Certified manufacturers follow strict design and process controls that help catch problems early. This includes things like:

Environmental and stress testing

Design verification at each stage

Process controls for winding, potting, and soldering

Full performance testing for every build

The result is better consistency, fewer unexpected issues, and higher confidence that each part will perform as designed. And while these benefits are critical in aerospace, they also help across industries where failure isn’t an option.

Many industries face the same performance challenges as aerospace—just in different forms. That’s why AS9100 certified magnetics are gaining traction in other high-reliability fields:

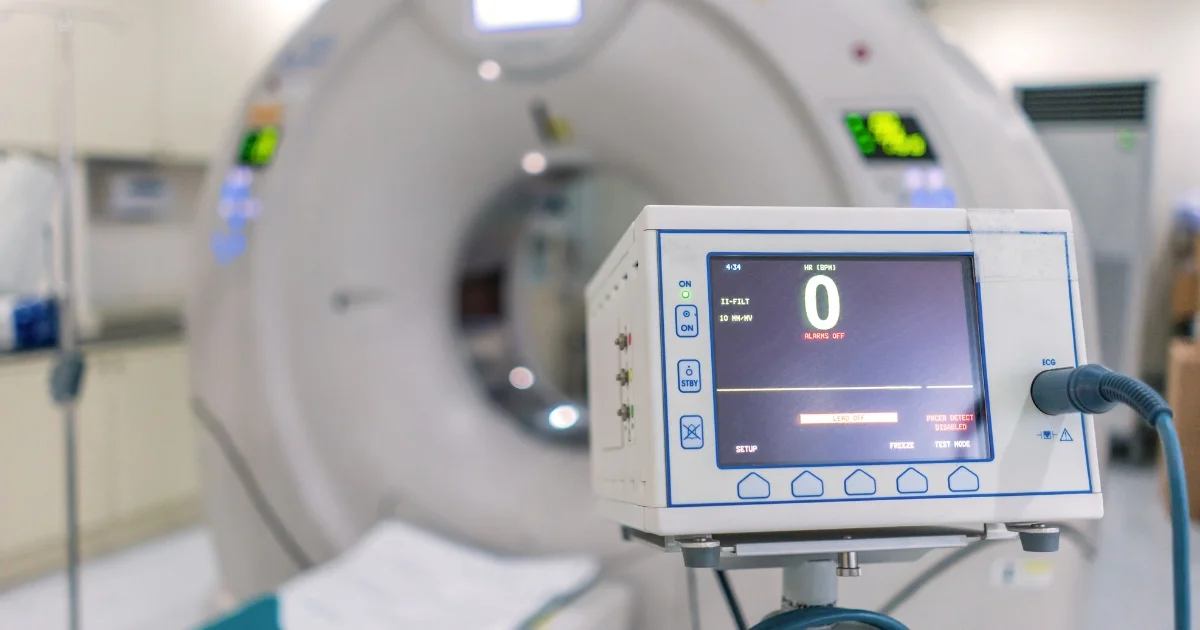

Systems like MRI machines, patient monitors, and diagnostic tools need components that are stable and trustworthy. Transformers and inductors designed under AS9100 can support these requirements with proven reliability and traceability.

Military communications and field systems operate in tough conditions. The quality controls required by AS9100 help ensure that magnetic parts can handle vibration, temperature shifts, and long-term use without failure.

Solar and wind equipment often runs for years with little downtime. Components built under AS9100 guidelines bring long-term durability to converters, inverters, and control systems exposed to outdoor conditions.

High-vibration environments like trains or factory floors place stress on every part. Magnetics built under AS9100-certified processes are designed to meet those demands.

Uptime is critical in networks and signal systems. Components built to strict standards—like those required in aerospace—can help reduce maintenance and improve system availability.

Working with a certified manufacturer gives OEMs and engineers:

More predictable performance

Clear documentation for compliance or traceability

Less risk of production issues or late-stage changes

Easier onboarding into regulated environments

Whether the end system flies or not, AS9100 certified magnetics help build stability into complex designs—and that matters everywhere.

AS9100 certification isn’t just a label—it reflects a full quality system that affects how a manufacturer works at every level.

Reviewing current processes through a gap analysis

Developing updated procedures and documentation to meet AS9100 standards

Implementing quality systems across all operations

Completing a pre-assessment to identify any weak points

Undergoing a formal certification audit by an accredited third-party organization

Yearly surveillance audits to review key processes

Internal audits to ensure continuous alignment with the standard

Management reviews to track system performance

Documented corrective actions for any issues found

Full recertification every three years to maintain the certification

For transformer and inductor manufacturing, certification adds an extra layer of discipline. It includes:

Verifying and tracking all materials used

Validating key steps like winding and impregnation

Running environmental tests that match real-world use

Monitoring critical performance metrics through process control

Keeping detailed records of every design, procedure, and test result

This commitment to quality continues throughout the product’s life—from design and production to final delivery and field use. The system helps reduce risk at every stage, supporting things like counterfeit part prevention, failure tracking, and using customer feedback to improve over time.

Many manufacturers hold ISO9001 certification, which shows they follow basic quality management practices. It’s a solid foundation, but AS9100 takes things further—especially for industries that demand high reliability, like aerospace or advanced electronics.

General quality management system requirements

A process-based approach to production

Customer satisfaction and feedback

Continuous improvement practices

Detailed regulatory compliance and documentation

Strong risk management throughout the product lifecycle

Emphasis on product safety and key feature identification

Configuration and change management controls

Tighter process validation and operational discipline

You can think of AS9100 as ISO9001 designed for mission-critical environments. These extra requirements aren’t just formalities—they help address real-world challenges where a single failure can cause major problems.

For custom magnetics manufacturers, AS9100 leads to stronger design systems, better process control, and more complete testing. That means more dependable components, whether they end up in aerospace or anywhere else performance matters.

Not all AS9100 certified manufacturers operate the same way. For teams sourcing high-reliability magnetics, it’s not just about earning the certification—it’s about how well those quality practices are built into everyday production.

A good partner will have in-house capabilities for key steps like winding, potting, encapsulation, and testing. These operations directly affect how magnetic components behave—especially in demanding systems where temperature, voltage, or size constraints come into play.

Electronic Craftsmen, for example, supports multiple winding formats, including toroidal and rectangular winding. This flexibility makes them a strong fit for both compact layouts and high-current designs.

It’s also worth asking whether the manufacturer provides custom magnetics, not just catalogue parts. Complex systems often need transformers or inductors tuned to specific power levels, frequencies, or mechanical constraints. Partners that offer design support, prototyping, and simulation tools can help ensure the magnetic components work exactly as intended within your larger system.

For harsh or high-risk environments, advanced testing capabilities are essential. Thermal cycling, and partial discharge detection (Corona), help validate that components will perform as expected—not just in lab conditions, but in the field over time.

Ultimately, selecting the right magnetics partner means finding a team that brings more than compliance. It’s about working with engineers who understand your application, build for long-term consistency, and have the tools to support precision at every step of the process.

AS9100 certification is more than a formality—it reflects a manufacturer’s full commitment to quality across design, production, and testing. For magnetic components, that means tighter controls, deeper documentation, and higher confidence in performance, especially when failure isn't an option.

Working with an AS9100 certified magnetics manufacturer gives you more than a finished part. It gives you visibility into the process behind that part—how it was designed, built, and verified to perform as expected. That kind of process discipline leads to better outcomes, whether you're developing systems for aerospace, energy, defense, or industrial applications.

The value of AS9100 doesn't end with compliance. It supports long-term reliability, smoother onboarding for regulated projects, and fewer surprises during testing or integration. The same principles that keep aircraft systems running safely help reduce risk in every environment.

If your application demands performance under pressure—whether in the air, on the ground, or in mission-critical systems—partnering with an AS9100 certified manufacturer gives you more than peace of mind. It gives you a clear advantage: proven process control, documented reliability, and components built to meet tight specs without cutting corners.

Choosing a partner like Electronic Craftsmen means building with confidence from the start. Because when failure isn’t an option, neither is guesswork.

Your equipment is down. The transformer failed—and replacements haven’t existed for years. Every day offline costs thousands. Without that magnetic component, the entire system stalls. This scenario plays out in factories, military installations, and medical facilities every day.

Legacy equipment often remains functional and valuable long after manufacturers discontinue support. When magnetic components fail in these systems, operators face difficult choices: expensive equipment replacement, risky third-party alternatives, or complete system retirement.

For effective legacy equipment repair, reverse engineering magnetics offers another path—recreating essential transformer components even when original documentation no longer exists. By carefully analyzing failed components, specialists can develop replacement parts that match or even improve upon original specifications—extending equipment life and avoiding costly system replacements.

Reverse engineering magnetics means disassembling failed transformers or inductors to uncover their exact design and performance. Like solving a puzzle with missing pieces, engineers must decode not just what it did—but how.

The process typically includes:

Physical examination of the damaged component

Careful disassembly (often destroying the original)

Documentation of winding patterns, wire sizes, and core materials

Electrical testing to determine key parameters

Recreation of design specifications

Prototype development and testing

Production of replacement components

For equipment manufacturers and maintenance teams, this process can salvage mission-critical systems when original parts are no longer available. It's particularly valuable in industrial, aerospace, medical, and military applications where equipment lifecycles often exceed component availability.

Legacy systems in aerospace, defense, and medical industries were built to last—but their magnetics weren’t. As components degrade, support disappears, and OEM replacements become impossible to find, creating what McKinsey & Company calls a growing “obsolescence challenge” for OEMs in industrial and defense sectors.

Finding exact replacements becomes nearly impossible. This creates serious problems, especially in highly regulated industries where swapping parts isn't just about function—it's about compliance. Medical devices, defense systems, and aerospace equipment all require strict validation for any component changes. Even when a similar transformer might electrically work, it could violate certification requirements or safety standards.

When critical infrastructure relies on legacy equipment, the cost of total system replacement often far exceeds the cost of reverse engineering a single component. In many cases, reverse engineering can save tens or even hundreds of thousands of dollars while getting systems back online in days rather than weeks or months.

Not every situation calls for reverse engineering. Sometimes, standard replacements or complete system upgrades are more practical. Reverse engineering typically makes the most sense when:

The equipment holds significant operational or financial value

Replacement systems would require extensive redesign, recertification, or retraining

Compliance-sensitive industries (AS9100, ISO9001, medical) need exact replacements

Downtime costs are extremely high

Original manufacturers no longer support the equipment

The unique magnetics are no longer manufactured

But there are limitations. Very complex designs with proprietary materials or specialized components may be difficult or impossible to reproduce. And without certain key information, engineers might need to make educated guesses about some specifications.

In December 2017, an electronic repair firm approached Electronic Craftsmen with a challenge. They had multiple GE power supplies failing due to problematic transformers. With no design documentation available and more units failing daily, they needed a solution fast.

The customer provided epoxy-sealed transformer samples, traced circuit board layouts, and created a sketched schematic. They also took inductance measurements and captured oscilloscope traces. From this limited information, our team identified the component as a "Gate Drive Transformer"—a device that couples gate-drive circuits to MOSFETs and IGBTs, modifies voltage levels, matches impedance, and provides isolation.

Space constraints on the circuit board made the replacement design challenging. To understand the internal construction, we dissolved the epoxy encasing the failed transformer. This revealed critical details about wire size and turn ratio. Based on the exposed physical characteristics and electrical parameters, we developed an entirely new design.

The original used a toroidal core, but our redesign employed an EFD20 platform using 3F3 core material. The gate side utilized triple-insulated TEX-E magnet wire. Drawing on our experience, we determined that expensive epoxy molding wasn't necessary—a simple air-dry varnish would suffice, reducing costs.

After confirming fit, the customer ordered 10 prototypes. We shipped them within a week. By late February, the transformers were field-tested and approved—followed by a 50-unit reorder. The entire project—from problem identification to field-tested solution—took just two months. Read the full GE power supply case study.

Reproducing magnetic components isn't always straightforward. Engineers commonly face these obstacles:

Without original design documents, engineers have to work backward from a failed component. It’s like trying to rebuild a custom tool just by looking at a broken one—you can measure the obvious dimensions, but the exact materials, internal layering, or subtle design choices aren’t always visible. And sometimes, those are the details that matter most.

Varnishes, insulation methods, and winding techniques all impact performance but may not be immediately obvious. An experienced engineer must make informed decisions about these details based on application requirements and physical evidence.

Core materials significantly impact transformer performance. Ferrite compositions, silicon steel grades, and specialized alloys each have unique electromagnetic properties. Identifying the exact material in a decades-old component can be nearly impossible.

Today's material options often differ from those available when legacy equipment was manufactured. Engineers must select modern equivalents that provide similar or better performance characteristics without altering the component's function in the system.

Legacy equipment wasn't designed with replacement in mind. Space limitations, unusual mounting methods, and unique connection types all restrict redesign options. The replacement must fit exactly where the original did—both physically and electrically.

In aerospace applications, this challenge often intensifies. Reverse-engineered components must meet strict physical and functional criteria—including dimensions, mounting methods, and sometimes weight distribution—to maintain compliance and performance. This article explains why these factors are critical when duplicating flight-certified components.

Reverse engineering isn't just about creating exact copies. It offers opportunities to improve on original designs using modern materials and techniques:

Legacy transformers often fail due to heat. Modern insulation and winding techniques improve thermal management—delivering better heat dissipation while preserving original specs and footprint.

Original equipment often used materials and techniques that have been surpassed by modern alternatives. Triple-insulated wire, advanced core materials, and better varnishes can extend component lifespan significantly. This makes reverse-engineered replacements potentially more reliable than the originals they replace.

Original designs sometimes used expensive manufacturing methods that are no longer necessary. In the GE power supply case study, switching from epoxy molding to air-dry varnish reduced costs without compromising performance.

But some changes risk altering component behavior in unpredictable ways. Engineers must carefully balance potential improvements against the need for functional equivalence. This requires both technical expertise and practical experience with legacy systems.

When facing legacy equipment failures, consider these factors before choosing reverse engineering:

System Value: Does the equipment's operational or financial value justify custom component development?

Urgency: Can you tolerate extended downtime while replacements are developed?

Complexity: Are the failed components suitable for reproduction?

Documentation: What information is available about the original design?

Quantity Needed: Will you need multiple replacements now or in the future?

Reverse engineering might cost more than off-the-shelf components initially, but when evaluated as part of a comprehensive legacy equipment repair strategy, it often proves more economical than complete system replacement. It's particularly valuable when you need multiple replacements over time or when a single component failure would sideline expensive equipment.

Reverse engineering magnetics requires specialized knowledge, testing capabilities, and manufacturing expertise. Electronic Craftsmen brings over 60 years of custom magnetics and power electronics experience to each reverse engineering project.

With AS9100 and ISO9001 certifications, Electronic Craftsmen meet the stringent quality standards required by aerospace, defense, and medical industries. This matters when recreating components for critical systems where failure isn't an option.

The company maintains in-house tooling, material sourcing, and comprehensive testing capabilities—essential for accurately reproducing legacy components. Their experience spans aerospace, defense, industrial, and telecommunications applications, providing the knowledge base needed to tackle diverse magnetic designs.

This expertise means they're not just making parts—they're replicating performance-critical solutions that must function exactly like the originals in complex systems.

Magnetic components are often the weakest link in otherwise reliable legacy systems. When these custom parts fail, entire production lines, labs, or communication systems can come to a standstill. But reverse engineering can bring them back to life.

Advances in materials and design now make it possible to recreate magnetic components that match—or even improve on—original specs. With the right expertise, decades-old equipment can keep running efficiently.

A failed transformer doesn’t have to mean system retirement. Contact us before replacing valuable legacy equipment. Even without documentation, their engineers can often develop a working solution that restores full functionality.

You don’t have to choose between full system replacement and costly downtime. Many legacy systems still have years of performance left—with the right magnetic solutions behind them. Why not explore an option that could save time, money, and extend the life of your most trusted equipment?

Power supply problems can arise in many ways. When hospital diagnostic equipment produces a blurry image; or train systems malfunction, four key power supply design components are usually involved: inductors, chokes, reactors, and filters. Each one controls power differently and selecting the wrong components during power supply design risks complete equipment failure.

In high reliability settings such as aerospace and medical facilities, power supply issues can cause equipment overheating, incorrect readings, or equipment that stops working completely. As an example, hospital imaging machines need special filters for clear imaging. A second example can be train systems that need powerful reactors to handle massive electrical loads. Off the shelf components often can't handle these tough jobs.

Different equipment needs different power solutions. Medical equipment must have clean, steady power. Aircraft systems need reliable power for safety. Factory machines need stable power to keep running. When basic components aren't enough, custom-designed solutions protect this critical equipment from failure.

This guide explains what makes each power component different and when you need custom versions. Whether you work with simple equipment or complex systems, knowing these differences helps avoid costly mistakes.

An inductor is used to introduce Inductance (L) into an electric circuit, preventing sudden changes in current flow. When a current (i) flows through the coil of an inductor, it develops a voltage potential (e) across its contact leads. This process allows the inductor to temporarily store electrical energy in a magnetic field within the core and around the coil. The core enhances the inductance and efficiency by concentrating magnetic flux lines within a closed magnetic path structure, helping to stabilize power inconsistencies.

An inductor's performance is determined by factors such as core material, wire gauge, air gap, and the number of turns in the coil. Most inductors use iron, ferrite, or air cores, each offering different characteristics for specific applications. The number of turns and the core type influence the strength of the magnetic field, directly affecting how the inductor functions within a circuit. For a deeper look at how inductors work, this technical guide from Bel Fuse covers their role alongside chokes, reactors, and filters.

You'll find inductors hard at work in many important industrial systems, such as:

In solar and wind power installations, they help convert unstable power into smooth, usable electricity.

Inside factory robots and automated systems, they keep power steady, so machines run smoothly.

In medical imaging equipment, they filter out electrical noise that could blur important diagnostic images.

While standard inductors work for basic jobs, you need a custom solution when your system requires a specific voltage or frequency range, when you're working with tight spaces or weight limits, or when your equipment operates in tough conditions like extreme heat or vibration.

Getting the right inductor, especially when you need a custom one, isn't just about making things work. It's about making them work reliably and efficiently for years to come. That's why engineers spend so much time choosing exactly the right inductor for each job.

A Choke is an Inductor type with or without a ferromagnetic core, used to block, hence “choke”, alternating current (AC) in a circuit by limiting the rate of change over a specified frequency range, while allowing passage of lower frequency AC or direct current (DC). This effect is often used in power supply circuits where the public AC mains (line) supply has to be converted to a DC supply suitable for powering electronic circuits.

In critical equipment like medical scanners or aircraft systems, this type of inductor protects against power disturbances that could cause equipment damage or system failures.

There are two main types of chokes, each designed to handle different forms of interference.

Common-mode chokes target interference affecting multiple power lines at once. Medical imaging systems need these to maintain diagnostic accuracy. Aircraft navigation depends on them for reliable signal quality. A failure in common-mode filtering could lead to blurred scans or corrupted flight data. These components are especially crucial in environments with high external interference.

Differential-mode chokes handle interference between individual power lines within a system. Manufacturing facilities rely on them to protect automated equipment from internal power fluctuations. Without proper filtering, voltage spikes could damage expensive machinery or halt production entirely. In industrial settings, these chokes often prevent costly downtime and equipment damage.

Chokes are widely used in hospitals, aircraft, factories, and data centers, where clean power is a necessity. In medical applications, chokes help maintain diagnostic accuracy, ensuring reliable imaging results. Aerospace electronics depend on them to keep communication and navigation systems free from interference. In industrial automation, they prevent voltage fluctuations from disrupting robotic precision and production efficiency.

While standard chokes work in many applications, some industries require specialized designs. Extreme electrical noise, unique frequency requirements, or strict regulatory compliance may demand custom chokes tailored to specific operating conditions. In these cases, engineered solutions provide the precise filtering needed to ensure uninterrupted performance and system longevity.

Reactors are large electrical reactors that keep industrial power systems stable and protected. Unlike regular inductors, these parts handle huge electrical loads, stopping power surges that can damage costly machines or shut down entire operations.

The science behind reactors is straightforward but critical. They create controlled electrical impedance in power circuits, acting as a barrier against voltage spikes and harmonic distortion. Without this protection, power fluctuations could overheat motors, trigger system failures, or cause widespread equipment damage.

Line Reactors guard industrial systems against power surges. When voltage suddenly spikes, these reactors absorb the excess power that would otherwise destroy factory equipment, HVAC systems, or motor drives.

Harmonic Reactors tackle power quality issues caused by modern electronic equipment. Variable frequency drives (VFDs) and uninterruptible power supplies can create electrical noise that strains systems. These reactors clean up the power, keeping equipment running within safety standards.

Load Reactors protect motors from electrical stress. In mining operations, railways, and industrial automation, motors need consistent power to function reliably. These reactors prevent overheating and control startup current surges.

Reactors play a vital role in power plants, transportation systems, manufacturing facilities, and renewable energy infrastructure – anywhere stable power distribution is necessary. In high-voltage substations, reactors help prevent electrical overloads that could cause grid instability. In electric train systems, they regulate power flow to traction motors, ensuring safe and efficient operation.

While standard reactors work in many applications, some systems require custom-engineered solutions to handle specific voltage levels, frequency conditions, or environmental constraints. Reactors designed for extreme temperatures, high-vibration environments, or unique electrical loads provide greater reliability and efficiency compared to off-the-shelf models.

Power filters remove unwanted electrical noise and interference from power systems. Unlike basic surge protectors, these components provide sophisticated frequency control, ensuring equipment gets clean, stable power. This filtering capability is crucial in medical facilities, electronics manufacturing, and communications systems where signal quality directly affects performance.

Filters use specific combinations of electrical components to control which frequencies pass through. Through careful design of inductors and capacitors, they create paths that trap interference while allowing desired power signals to flow. This selective blocking prevents both electromagnetic (EMI) and radio frequency (RFI) interference from disrupting sensitive equipment.

Different types of filters handle different jobs:

Low-pass filters block high-frequency interference while allowing lower frequencies through. These protect power supplies and sensitive electronics from fast-changing electrical noise that could cause malfunctions.

High-pass filters do the opposite - they block low-frequency interference while allowing high-frequency signals to pass

Bandpass filters are more selective, allowing only specific frequency ranges to pass through. Medical imaging equipment relies on these for precise signal control and clear diagnostic results.

EMI filters handle a specific challenge: electromagnetic interference. They shield sensitive electronic systems from the electrical noise generated by motors, power lines, and wireless devices. In industrial settings, where heavy machinery operates near delicate control systems, EMI filtering prevents equipment failures and data corruption.

Filters protect essential equipment in some of the toughest conditions. In hospitals, they keep power steady for accurate test results – one small power problem could affect patient care. Telecommunications centers rely on them to keep data flowing smoothly through their delicate communication systems. Without proper filtering, important messages could be lost.

Manufacturing facilities need filters to protect precision machinery. Modern factory floors run on complex automated systems that depend on clean, stable power. Even minor electrical interference can throw off calibration or cause expensive production errors. Research laboratories face similar challenges, where delicate scientific instruments need pristine power conditions for accurate measurements.

While standard filters handle common interference problems, many specialized applications demand custom solutions. High-tech medical equipment might need filters designed for specific frequency ranges. Data centers often require filters that can handle unusual power loads or meet strict performance standards. Manufacturing equipment might face harsh electrical environments that overwhelm basic filters.

Custom-engineered filters become essential when standard components can't meet these challenges. Whether it's dealing with high-frequency noise, meeting strict regulatory requirements, or handling unusual power conditions, these specialized filters ensure reliable operation where standard units would fail. In critical applications where clean power directly affects performance and safety, custom filtering solutions protect both equipment and operations.

Choosing the right electrical component requires matching your system's exact needs. Whether you need an inductor, choke, reactor, or filter, getting it wrong can lead to equipment damage or system failure.

Key Selection Factors:

Power and Frequency Needs: Components must handle your specific power levels and electrical signals

Environmental Requirements: Consider heat, vibration, and moisture resistance needs

Load Capacity: Ensure components can handle your system's full electrical load

Safety Standards: Match industry-specific requirements for medical, aerospace, or industrial use

Think of custom components as an investment in reliability. While they might cost more upfront, they can prevent expensive problems down the road. For critical systems where failure isn't an option, custom-engineered solutions often provide the best long-term value.

From medical equipment to high-speed trains, the right power components keep critical systems running safely. Whether you need an inductor, choke, reactor, or filter, choosing the wrong one risks expensive repairs or dangerous failures. Custom solutions provide the reliability these systems need to run safely and meet all requirements.

Ready to find the right solution? Let's discuss your specific needs.