We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

In aerospace, there’s no room for guesswork. Every component—no matter how small—must meet the highest standards. That’s why AS9100 exists. It’s the gold standard for quality management in aerospace manufacturing, created to ensure parts are built with precision, tested for reliability, and fully traceable at every step.

However, this certification isn’t just for planes and satellites. The same systems that keep aircraft safe are now guiding how many teams build parts for energy, medical, defense, and communications. And for components like transformers, inductors, and magnetic assemblies—where performance depends on exact design and materials—that kind of structure makes a real difference.

This post breaks down what AS9100 certification really involves, how it applies to magnetics, and why working with an AS9100-certified manufacturer is a smart move—even if you’re not building for aerospace. Whether your system operates at high altitudes or deep in a control cabinet, quality still matters.

AS9100 is a quality management standard created specifically for aerospace and defense. It’s built on ISO 9001 but adds deeper requirements that reflect the complex needs of flight systems. For custom magnetics manufacturers, it means every step of the process—from design to testing—is held to some of the highest standards in the industry.

AS9100 covers areas like:

Full traceability of materials

Detailed documentation for every step

Risk-based decision-making during development

Strict testing and verification processes

Oversight of suppliers to prevent issues with quality or counterfeits

Getting certified isn’t easy. It involves a full audit by an accredited body, along with proof that processes are stable and consistent. Not all manufacturers meet these standards.

Once certified, companies don’t stop there. AS9100 requires yearly audits and full recertification every three years. That ongoing process helps ensure manufacturers stay focused on improvement—not just passing a one-time check.

Magnetics often fly under the radar—until something goes wrong. But components like transformers and inductors are critical in nearly every system that depends on clean, stable power. When these parts fail, the results can be serious.

In aerospace, even a small shift in performance can affect everything from flight control to communication. Magnetic components must survive vibration, extreme temperatures, and sometimes radiation, all while maintaining their exact performance specs.

That’s where AS9100 makes a difference. Certified manufacturers follow strict design and process controls that help catch problems early. This includes things like:

Environmental and stress testing

Design verification at each stage

Process controls for winding, potting, and soldering

Full performance testing for every build

The result is better consistency, fewer unexpected issues, and higher confidence that each part will perform as designed. And while these benefits are critical in aerospace, they also help across industries where failure isn’t an option.

Many industries face the same performance challenges as aerospace—just in different forms. That’s why AS9100 certified magnetics are gaining traction in other high-reliability fields:

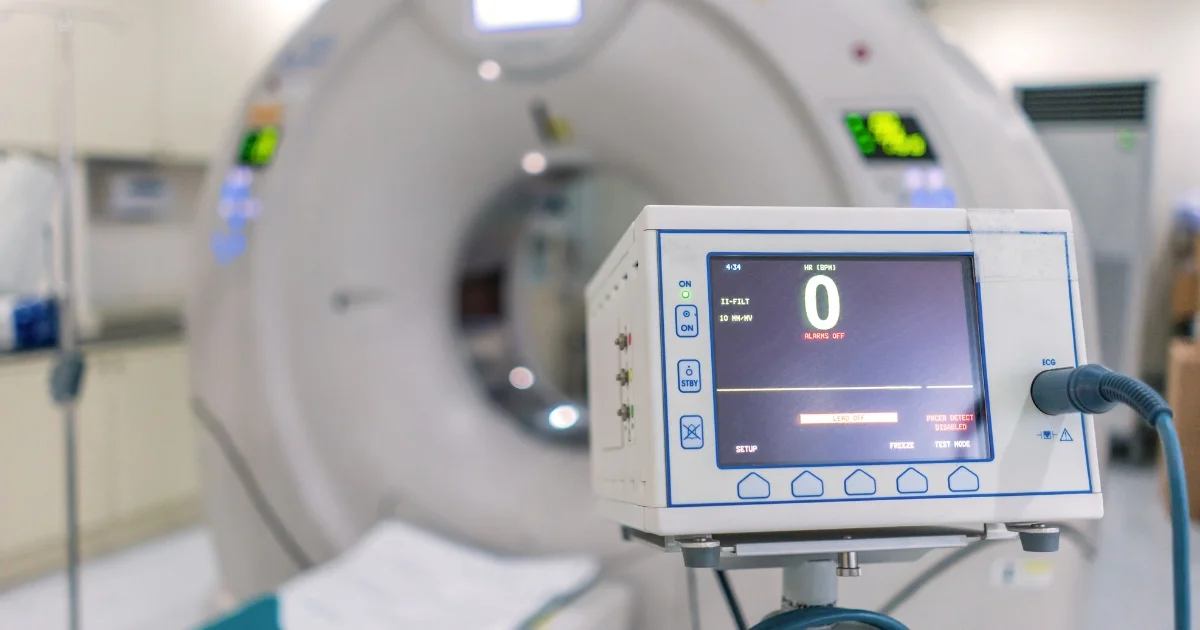

Systems like MRI machines, patient monitors, and diagnostic tools need components that are stable and trustworthy. Transformers and inductors designed under AS9100 can support these requirements with proven reliability and traceability.

Military communications and field systems operate in tough conditions. The quality controls required by AS9100 help ensure that magnetic parts can handle vibration, temperature shifts, and long-term use without failure.

Solar and wind equipment often runs for years with little downtime. Components built under AS9100 guidelines bring long-term durability to converters, inverters, and control systems exposed to outdoor conditions.

High-vibration environments like trains or factory floors place stress on every part. Magnetics built under AS9100-certified processes are designed to meet those demands.

Uptime is critical in networks and signal systems. Components built to strict standards—like those required in aerospace—can help reduce maintenance and improve system availability.

Working with a certified manufacturer gives OEMs and engineers:

More predictable performance

Clear documentation for compliance or traceability

Less risk of production issues or late-stage changes

Easier onboarding into regulated environments

Whether the end system flies or not, AS9100 certified magnetics help build stability into complex designs—and that matters everywhere.

AS9100 certification isn’t just a label—it reflects a full quality system that affects how a manufacturer works at every level.

Reviewing current processes through a gap analysis

Developing updated procedures and documentation to meet AS9100 standards

Implementing quality systems across all operations

Completing a pre-assessment to identify any weak points

Undergoing a formal certification audit by an accredited third-party organization

Yearly surveillance audits to review key processes

Internal audits to ensure continuous alignment with the standard

Management reviews to track system performance

Documented corrective actions for any issues found

Full recertification every three years to maintain the certification

For transformer and inductor manufacturing, certification adds an extra layer of discipline. It includes:

Verifying and tracking all materials used

Validating key steps like winding and impregnation

Running environmental tests that match real-world use

Monitoring critical performance metrics through process control

Keeping detailed records of every design, procedure, and test result

This commitment to quality continues throughout the product’s life—from design and production to final delivery and field use. The system helps reduce risk at every stage, supporting things like counterfeit part prevention, failure tracking, and using customer feedback to improve over time.

Many manufacturers hold ISO9001 certification, which shows they follow basic quality management practices. It’s a solid foundation, but AS9100 takes things further—especially for industries that demand high reliability, like aerospace or advanced electronics.

General quality management system requirements

A process-based approach to production

Customer satisfaction and feedback

Continuous improvement practices

Detailed regulatory compliance and documentation

Strong risk management throughout the product lifecycle

Emphasis on product safety and key feature identification

Configuration and change management controls

Tighter process validation and operational discipline

You can think of AS9100 as ISO9001 designed for mission-critical environments. These extra requirements aren’t just formalities—they help address real-world challenges where a single failure can cause major problems.

For custom magnetics manufacturers, AS9100 leads to stronger design systems, better process control, and more complete testing. That means more dependable components, whether they end up in aerospace or anywhere else performance matters.

Not all AS9100 certified manufacturers operate the same way. For teams sourcing high-reliability magnetics, it’s not just about earning the certification—it’s about how well those quality practices are built into everyday production.

A good partner will have in-house capabilities for key steps like winding, potting, encapsulation, and testing. These operations directly affect how magnetic components behave—especially in demanding systems where temperature, voltage, or size constraints come into play.

Electronic Craftsmen, for example, supports multiple winding formats, including toroidal and rectangular winding. This flexibility makes them a strong fit for both compact layouts and high-current designs.

It’s also worth asking whether the manufacturer provides custom magnetics, not just catalogue parts. Complex systems often need transformers or inductors tuned to specific power levels, frequencies, or mechanical constraints. Partners that offer design support, prototyping, and simulation tools can help ensure the magnetic components work exactly as intended within your larger system.

For harsh or high-risk environments, advanced testing capabilities are essential. Thermal cycling, and partial discharge detection (Corona), help validate that components will perform as expected—not just in lab conditions, but in the field over time.

Ultimately, selecting the right magnetics partner means finding a team that brings more than compliance. It’s about working with engineers who understand your application, build for long-term consistency, and have the tools to support precision at every step of the process.

AS9100 certification is more than a formality—it reflects a manufacturer’s full commitment to quality across design, production, and testing. For magnetic components, that means tighter controls, deeper documentation, and higher confidence in performance, especially when failure isn't an option.

Working with an AS9100 certified magnetics manufacturer gives you more than a finished part. It gives you visibility into the process behind that part—how it was designed, built, and verified to perform as expected. That kind of process discipline leads to better outcomes, whether you're developing systems for aerospace, energy, defense, or industrial applications.

The value of AS9100 doesn't end with compliance. It supports long-term reliability, smoother onboarding for regulated projects, and fewer surprises during testing or integration. The same principles that keep aircraft systems running safely help reduce risk in every environment.

If your application demands performance under pressure—whether in the air, on the ground, or in mission-critical systems—partnering with an AS9100 certified manufacturer gives you more than peace of mind. It gives you a clear advantage: proven process control, documented reliability, and components built to meet tight specs without cutting corners.

Choosing a partner like Electronic Craftsmen means building with confidence from the start. Because when failure isn’t an option, neither is guesswork.

In magnetics manufacturing, production delays often start at the supplier level. Vendor relationships, then, aren’t just a procurement concern. They’re a core part of performance, especially when you’re delivering high-reliability magnetics for industries like aerospace, green tech, or automation.

When transformers, inductors, and custom assemblies need to meet demanding specs, timeline precision and quality assurance become inseparable. At Electronic Craftsmen, we’ve seen firsthand how the right partnerships can make or break an order. That’s why we’ve spent over a decade working with vetted vendors who understand the stakes—and operate with the same standards of precision we do.

Outsourcing isn’t new in electronics. But when it comes to magnetic components, many teams still underestimate the hidden risks of choosing offshore vendors with no proven track record.

On paper, a lower unit cost might look like a win. But when quality issues surface or timelines fall apart, that initial savings disappears. Common issues include:

Inconsistent quality control: A core material substitution, a sloppy winding pattern, or an under-cured encapsulation can lead to early failures and field returns.

Communication breakdowns: Language barriers, engineering misinterpretations, or lack of real-time visibility can derail even simple adjustments.

Timeline disruptions: Customs delays, unexpected shortages, or inflexible shipping timelines can grind your build schedule to a halt.

These risks are amplified in high-spec sectors like aerospace and defense. We’ve seen programs stall over millimetre deviations and missed test protocols. That’s why every component in our supply chain is QA-tested, traceable, and sourced through relationships that prioritize long-term reliability.

These real-world obstacles demonstrate why Electronic Craftsmen maintains rigorous qualification standards. We don’t just approve vendors; we integrate them into our process. That means ongoing quality audits, spec reviews, and process feedback loops that catch issues early and prevent them from recurring.

Our goal isn’t just to find a supplier. It’s to maintain a supply chain that operates at the same level of engineering discipline we apply internally.

Many of Electronic Craftsmen’s vendor partnerships go back more than ten years. That history creates a level of alignment that’s hard to replicate with new or untested suppliers. When a vendor understands not just what you’re building, but why certain specs matter, the entire process runs smoother.

These partnerships bring real advantages:

Shared context: Vendors familiar with our transformer geometries or potting requirements don’t need re-training on every order.

Proactive adjustments: A trusted vendor will flag a material lot that could compromise dielectric strength before it ever reaches the floor.

Faster iteration cycles: When design tweaks happen mid-program, our vendors can pivot quickly—because they’re already aligned on quality benchmarks.

That kind of embedded understanding becomes critical when tolerances are tight, specs are complex, and deadlines leave no room for error.

It’s also what enables flexibility under pressure. Whether it’s a sudden ramp-up in production or a last-minute change to thermal insulation standards, long-standing partners are more likely to adapt without causing delays.

And when global material shortages hit, it’s those same relationships that quietly keep things moving.

Electronic Craftsmen doesn’t avoid offshore sourcing—we optimize it. Our approach balances global reach with domestic control, blending cost efficiency with full conformance. We partner with qualified international vendors for sourcing, but final assembly and QA happen here in Ontario.

Every part goes through:

Domestic inspection and functional testing using Voltech and in-house equipment

Thermal and corona testing in controlled lab conditions

Dielectric verification and visual QA to ensure zero defect delivery

This layered approach keeps costs in check while ensuring the same standards we’re known for: AS9100, ISO9001, MIL-PRF-27, and Class 220°C insulation conformance, just to name a few.

Some teams rely on our hybrid model to balance high-volume sourcing with aerospace-level QA. Others use our build-to-print services to localize complex winding or encapsulation steps. In every case, the vendor network is part of the solution—not the liability.

Our team handles complex builds requiring precision winding, multi-core assemblies, and encapsulation. Having this capability onshore allows us to move quickly when specs change, test requirements evolve, or a production delay needs a workaround. The offshore support provides material diversity and cost control. It’s a supply chain built to serve modern engineering needs without compromise.

In magnetics, time isn't just money—it's certification, audit-readiness, and launch clearance. A missed delivery window can mean rebooked test labs, late-stage redesigns, or lost client confidence. When a vendor consistently meets specs and timelines, they’re not just a supplier. They’re part of your risk mitigation strategy.

Our vendors know exactly how we prep, inspect, and pot these units. We build confidence into every quote, timeline, and customer commitment we make. That reliability becomes especially important in industries like rail and marine power systems, where environments are harsh and downtime is costly.

The ability to count on component consistency allows our clients to meet safety, reliability, and regulatory standards without added complexity. We’re proud to say many of our clients choose us not just for what we build but because of how predictable we make their operations.

Established magnetics manufacturers bring something invaluable to the table: a deep knowledge base built over thousands of projects. This experience translates to tangible benefits you can’t get from newer suppliers.

With over six decades of experience, Electronic Craftsmen has built a design library containing thousands of custom magnetic components. That archive is not just a number but a competitive advantage. In many cases, we’ve already solved variations of the challenges you’re facing today. Instead of starting from scratch, our team can adapt proven designs, reducing both development time and validation risk.

Experience also means having the right tools in place. Our facility includes vacuum encapsulation chambers, corona testing up to 20kVac, and thermal cycling capabilities ranging from -73°C to +190°C. These systems allow us to thoroughly validate performance in extreme conditions, long before any component reaches a customer site.

And perhaps most important: seasoned engineers. Our team knows which core materials excel in high-frequency switch-mode applications. We know how soldering methods affect long-term thermal behavior. And we know what tends to go wrong in aerospace, rail, or defense environments—because we’ve seen it. And we’ve built around it.

Magnetics is a specialized space. The performance of a custom inductor or pulse transformer depends on dozens of variables—core geometry, winding pattern, insulation class, soldering method, thermal behavior. Experience with these trade-offs makes vendors more than part suppliers. It makes them technical allies.

At Electronic Craftsmen, we extend that mindset into every design review. Whether we’re prototyping a high-voltage transformer for renewable energy or modelling thermal performance for a sealed assembly, our vendor network is looped in early. That means fewer surprises, faster validation, and smarter material use.

We continue delivering reliable custom magnetics without compromising on schedule or spec. From current sense transformers in lab equipment to ruggedized inductors for defense, every unit is an outcome of technical alignment and collaboration.

That collaboration often starts with vendor input during material selection, insulation review, or tooling considerations. Many of our vendors act as early-stage advisors, helping refine part manufacturability and reduce lead time risk before we ever wind a coil.

We also maintain a deep library of proven magnetic component designs, built over decades of production. This gives us the ability to adapt tested configurations to new challenges—helping reduce lead times and speed up qualification in industries where time to market is critical.

When evaluating magnetic component suppliers, it’s not just about specs or price points—it’s about trust, responsiveness, and long-term alignment.

Before you sign the next PO, ask:

Does this vendor understand our application environments and constraints?

Can they adapt to change without derailing timelines?

Do they bring engineering insight or just deliver parts?

The strongest vendor relationships don’t just check boxes. They improve outcomes across every stage of development and delivery.

In custom magnetics, consistent performance comes from more than in-house talent. It comes from the relationships that support your work behind the scenes.

That’s why Electronic Craftsmen has invested in vendor partnerships that last. Our network helps us meet demanding specs, turn around prototypes quickly, and avoid the hidden costs of poor communication or inconsistent QA. We don’t treat vendors as interchangeable. We treat them as extensions of our own commitment to reliability.

In this industry, long-term performance starts with long-term trust. Once earned, it becomes a key driver of resilience, innovation, and uptime for the clients we serve across aerospace, automation, and beyond.

If your next build demands precision, speed, and zero-surprise delivery—let’s talk. Our network is ready when you are.

As renewable energy systems advance, they place new demands on internal components. Nowhere is that more evident than in magnetics. Transformers and inductors are expected to perform reliably across temperature extremes, switching harmonics, and tight packaging constraints.

Solar, wind, and energy storage applications introduce unique technical challenges where off-the-shelf components may not be the best choice for system designers.

Custom magnetics, designed specifically for these applications, can help address these challenges at the earliest stages of system design. By considering unique environmental factors, high-frequency switching, thermal cycling, and system integration requirements, custom solutions can minimize the risks associated with reliability and performance.

This post explores the unique challenges magnetics face with respect to solar, wind, and battery systems—and how custom component design supports long-term reliability and system success.

Modern solar inverters are among the most demanding environments for magnetics. Central inverters at utility scale operate at high power levels with aggressive efficiency targets. String inverters and module-level devices often experience rapid changes in operating conditions, especially with passing clouds or fluctuating demand.

Switching frequencies above 50 kHz are common, introducing thermal stress and requiring magnetic cores that can operate efficiently at elevated temperatures. Standard potting compounds and windings may not hold up under these conditions, leading to premature failure.

Grid-connected solar systems must follow strict rules for harmonic distortion (THD). However, high-frequency switching tends to generate harmonics that need to be suppressed before they reach utility infrastructure. Standard magnetics may struggle to attenuate these signals effectively.

Custom magnetics can be tailored for:

Reduced core losses at high frequencies

Improved isolation distances to minimize EMI coupling

Winding techniques that balance capacitance and inductance

String inverters and rooftop-mounted devices are typically housed in compact enclosures. Limited airflow and outdoor exposure increase the risk of thermal buildup and moisture ingress. Off-the-shelf parts, often designed for controlled indoor use, may degrade quickly in such environments.

Custom solutions can:

Include encapsulation for humidity resistance

Utilize thermally stable winding materials

Be shaped for non-traditional footprints (e.g., vertical mount designs)

Wind turbines, particularly offshore and high-capacity units, present unique magnetic challenges. Generator systems can produce rapid current fluctuations, especially during startup or changes in wind speed. Inductors and transformers must be able to manage high inrush currents without saturating.

Where off-the-shelf inductors might saturate under these loads, custom components can be designed with:

Controlled saturation profiles

Distributed air gaps for smoother magnetic response

Core materials selected for high permeability and low loss

Wind turbines put magnetics in tough conditions. Their nacelles are high off the ground and constantly vibrating. Standard inductors may fail due to mechanical fatigue or resin cracking.

Custom magnetics for wind applications often include:

Reinforced bobbins and windings

Vacuum encapsulation for vibration dampening

Mechanical mounting features integrated into the component design

Variable-speed wind turbines often inject harmonics into the local grid, affecting other systems nearby. Custom filter inductors can be tuned to specific harmonic ranges to reduce these effects before they propagate.

Battery energy storage systems (BESS) require magnetics that can handle power flow in both directions—charging and discharging. This introduces different waveform shapes and current intensities, which many single-direction magnetics are not optimized for.

Custom transformers and inductors in this space are built to:

Maintain consistent inductance across polarity changes

Handle transient loads without distortion

Provide isolation under both charge and discharge conditions

Energy storage systems are often housed in sealed containers with limited airflow. Passive thermal management becomes essential. Custom magnetics help by minimizing internal heat generation through efficient core materials and winding layouts.

Strategies include:

Using core materials with low hysteresis and eddy current losses

Selecting winding techniques that reduce hot spots

Designing for natural convection pathways within the enclosure

Battery systems must maintain galvanic isolation, even during fault conditions. This requires insulation systems that hold up during thermal events or voltage surges. Custom magnetics can incorporate high-grade insulation and layout spacing that meet specific isolation standards.

Custom doesn’t just mean different. It means built with purpose. The value lies in:

Predictable thermal behaviour: Helps avoid derating and ensures consistent performance across temperature swings.

Consistent impedance and response: Reduces distortion and improves controller feedback accuracy.

Optimized footprint: Makes the most of limited enclosure space.

Environmental resilience: Withstands vibration, moisture, and thermal shock better than general-purpose parts.

These advantages often lead to:

Fewer field failures

Lower maintenance intervention

More consistent performance over product lifetime

While custom magnetics may involve longer lead times and validation steps, they mitigate the much higher cost of failure in mission-critical renewable applications.

Understanding the true impact of magnetic component failure helps justify the investment in custom solutions. Industry reports indicate that offshore wind component failures can result in multi-million-dollar replacement costs, particularly when specialized vessels and equipment are required.

According to a T&D World analysis on transformer resiliency, "the largest transformer loss on record occurred at a power plant, resulting in business interruption costs of more than $86 million" as reported by Willis Risk Solutions. The article emphasizes how transformers face electrical, thermal, and chemical stresses that can degrade insulating oils and lead to premature failure, highlighting why custom designs with enhanced durability are critical for renewable energy applications.

For solar installations, inverter-related failures average tens of thousands of dollars in physical damage alone, with business interruption costs often doubling that figure due to extended repair times. Research indicates that offshore wind turbines experience multiple failures annually, with major component replacements running into significant costs even before considering downtime.

Consider these hidden costs:

Emergency service calls to remote installations

System downtime during peak production periods

Warranty claims and customer satisfaction issues

Regulatory penalties for grid non-compliance

Reputation damage in competitive markets

Custom magnetics represent a strategic investment that prevents these cascading failures. While custom components cost more initially than standard catalogue parts, the investment becomes justifiable when compared to the potential failure costs and risk mitigation achieved.

Working with an experienced custom magnetics partner means identifying risks early. During the design phase, key considerations include:

Voltage and current range across all operating conditions

Target switching frequency and any harmonic constraints

Ambient and internal temperature profiles

Mechanical stress and vibration profiles

Size and shape constraints from system layout

Early prototyping and testing ensure that magnetics behave as expected under real-world conditions. Testing can include:

Partial discharge detection

Thermal imaging under load

Dielectric strength testing

Accelerated thermal cycling

Renewable energy systems demand high repeatability. Custom magnetics often require:

Precision winding (foil, toroid, rectangular)

Automated electrical testing (e.g., Voltech systems)

Vacuum encapsulation for environmental sealing

Ferrite core grinding for inductance tuning

Quality-focused manufacturers also offer:

Documentation for traceability

Lot-specific test reports

This level of control cuts down variation between batches. That’s key when you need identical performance in every unit.

A few key trends are shaping the future of magnetics in renewable energy:

Wide-bandgap semiconductors (SiC, GaN): Require magnetics that operate efficiently at MHz-level frequencies.

Digital monitoring integration: Sensors embedded into magnetics for predictive maintenance.

Modular magnetics designs: Enabling easier servicing and replacement.

Sustainable materials: Including recyclable cores and low-impact potting compounds.

Engineers are increasingly looking at magnetics not as standalone components but as part of an optimized power system. That system-level thinking drives more demand for custom designs.

Custom magnetics are not just about fit and form—they’re about risk management. In renewable energy systems where uptime, safety, and performance are all critical, the cost of guessing wrong is too high.

Working with experienced engineers from the outset allows teams to identify failure modes early, test more effectively, and build in confidence from the ground up. From the heat of a rooftop inverter to the vibration of a nacelle, well-designed magnetics can make the difference between a product that performs—and one that fails prematurely.

The challenges are real, but so are the solutions. And in a space where every watt counts, solving them starts at the core.

When renewable energy systems face unexpected failures or standard magnetic components limit design flexibility, the root cause often traces back to components that weren't built for these demanding applications. Electronic Craftsmen specializes in solving exactly these challenges.

Our engineering team has developed over 10,000 custom magnetic solutions across six decades. From high-frequency transformers that thrive in desert heat to inductors that withstand offshore vibration, we've tackled the toughest renewable energy applications.

Don't let magnetic component limitations hold back your renewable energy innovations. Schedule a consultation with our engineering team to discuss your specific challenges. We'll analyze your requirements, share insights from similar projects, and develop a custom solution that ensures long-term reliability.

Not all transformer core material performs the same, and the wrong choice can compromise your magnetics design. Core material affects how a transformer performs under load, how hot it gets, how much space it occupies, and even how much it costs to build and run.

While windings and insulation often get the spotlight, the core is doing the heavy lifting behind the scenes. It handles the magnetic energy flow, and the way it does that depends entirely on the material you choose.

This post looks at why transformer core material matters. You'll see how it impacts efficiency, size, and cost—and how the right expertise can help you pick the optimal material from the start.

At the heart of every transformer is the core. It's responsible for the transfer of magnetic energy through the magnetic device. The better the material at handling this transfer of power, the more efficient the device operates.

Every core material behaves differently. Some materials are better at high frequency switching than others (i.e. ferrite). Each one comes with its own limitations and drawbacks as it pertains to heat rise, signal distortion, and energy loss.

When the core material precisely matches the application, everything works better. As efficiency increases, losses go down. Size and weight are easier to control but when the material isn't a good fit, systems can run hot, lose power, or require larger parts to hit the same performance levels.

That’s why engineers spend time on magnetic core selection early in the design process—it’s one of the most critical choices in magnetic components.

Core material has a direct effect on how much energy your transformer uses—and how much it wastes. As current moves through the transformer, part of it turns into heat. Some materials hold that loss a minimum…others don't.

Ferrite, for example, performs well at high-frequencies and keeps energy losses low. Silicon steel is more rugged and works better at low frequencies, though it loses more power to heat. Powdered iron sits somewhere in the middle, offering balance between performance and strength.

Access to thermal modelling and performance testing early in the design process helps teams choose materials that keep losses low without risking overheating.

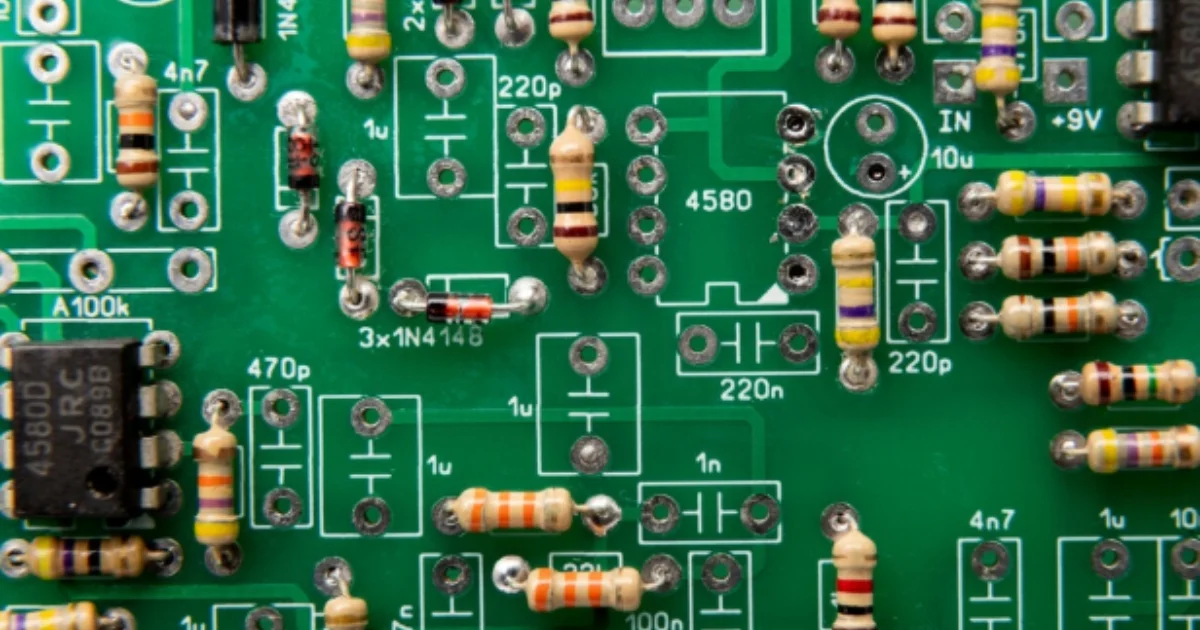

Core losses happen in two main ways: hysteresis loss and eddy current loss. Hysteresis loss occurs as the magnetic field repeatedly changes direction, creating friction at the molecular level. Eddy current losses happen when small electrical currents form within the core material itself.

Different materials combat these losses in different ways:

Silicon steel uses thin laminations to break up eddy currents

Ferrite naturally resists eddy currents with high electrical resistance

Powdered iron uses tiny, insulated particles to minimize both loss types

Nanocrystalline cores offer exceptional performance but at higher cost

Matching these properties to your specific frequency and operational range and duty cycle is crucial. But isn't a high-performing core always better? Not necessarily. Some applications might not justify the cost of premium materials if the efficiency gains aren't critical to the design requirements.

Different materials handle magnetic energy in different ways. That affects how large your magnetics need to be. Some high-performance materials allow for smaller core shapes because they hold more energy in less space. That's why ferrite and high-flux cores are common in aerospace and electric vehicle systems, where every gram matters.

In certain instances, size might be less critical, so designers might choose more affordable but heavier materials like laminated steel.

Material costs vary. Some are more expensive to shape. Others are harder to find. The right choice depends on your budget, timeline, and performance needs. Ferrite may cost more upfront, especially for custom shapes. But it can also reduce long-term energy loss and system heat.

Powdered cores are often easier to source and machine. Laminated steel is cost-effective for basic low frequency uses but less efficient over time. Working with vendors that offer a range of options helps teams avoid long delays or overspending on overbuilt designs.

The perfect core isn't just about electrical performance—it needs to physically survive its operating environment. Some materials offer excellent magnetic properties but poor mechanical strength.

Core materials must withstand:

Mechanical vibration and shock

Thermal cycling and expansion

Installation stress during winding and assembly

Environmental factors like humidity and corrosion

Ferrite is often recommended for high-frequency applications where electromagnetic interference (EMI) is a concern. But when mechanical durability matters more, encapsulated powdered iron cores can handle rougher conditions without cracking.

Precision machining helps teams meet tight specifications without overbuilding. This is particularly valuable for ferrite cores, where small adjustments to the physical dimensions can dial in exact inductance values without compromising performance.

Every industry comes with its own design constraints—and each one depends on the right core material to meet performance, safety, and cost goals. At Electronic Craftsmen, we support a wide range of applications, from aerospace to automation. Explore the industries we serve.

In aerospace systems, size, weight, and reliability are everything. Transformers often need to perform under high-vibration conditions and within tight thermal limits. That means using materials like ferrite, which can support high frequency switching in a compact footprint. Additionally, Electronic Craftsmen offers In-house ferrite grinding so designers can precisely meet stringent component requirements.

Lastly, our transformers are constructed to meet the requirements of standards such as MIL-PRF-27 for added reliability in demanding conditions.

In communications gear and high-frequency power systems, signal clarity and thermal stability are key. That's where ferrites and powdered iron cores often shine. These materials support faster switching speeds with fewer electromagnetic losses.

For low frequency applications such as in industrial and automation systems, Laminated steel magnetics are widely used. However, these components may be subject to environmental challenges such as high humidity, extreme temperatures, and industrial contaminates. Features like vacuum encapsulation, antifungal coatings, and epoxy coatings protect core materials in extreme conditions.

Transformer cores in renewable energy systems face unique challenges. Solar inverters, wind power generators, and energy storage setups all demand high efficiency core materials to make the most of limited energy capture—often while operating outdoors or in variable conditions.

For solar inverters, the core must support frequent load changes as sunlight shifts throughout the day. This dynamic environment favours materials with low hysteresis loss that can maintain performance across thousands of magnetic cycles. Ferrite and amorphous cores often fit the bill, offering solid efficiency at a reasonable cost.

Wind power adds another layer of complexity. These systems operate at variable frequencies and can face mechanical vibration that stresses brittle core materials. Cores need to handle that strain while staying efficient across changing electrical loads.

In EV charging and battery storage, transformers often use nanocrystalline or powdered metal cores. These materials support high-frequency switching while keeping transformer size compact—a key factor in modern power systems.

Thermal management is especially important in green tech, where transformers may be enclosed with limited cooling. Core materials that naturally run cooler help maintain efficiency in hot weather and extend system life.

We design custom magnetics for renewable energy with a focus on efficiency, temperature stability, and long-term reliability—helping your systems produce maximum power with minimum waste.

Choosing the right core material isn't just about specs—it's about solving a system-level challenge. That's where specialized magnetics manufacturers make the biggest impact.

Instead of guessing which material will work, you need hands-on support with electrical modeling, thermal simulations, and prototype testing. These tools help compare options based on actual performance, not just datasheets.

At Electronic Craftsmen, we offer in-house ferrite core grinding. That means parts can be built to tight inductance specs without needing a full layout change. This is especially useful when space is limited or when weight must be minimized without losing performance.

With both domestic and offshore vendor relationships, we source a wide range of materials—while still doing final testing and assembly in Canada to ensure quality. Whether your goal is cutting size, improving efficiency, or staying within budget, our team helps you design with the right material from the start.

Choosing the right core material doesn't just fine-tune your transformer—it shapes your system's future. From thermal losses and switching frequency to footprint and compliance, the core plays a central role in performance and cost.

That's why teams across aerospace, green energy, and industrial automation trust Electronic Craftsmen to help them make the right call—combining deep material knowledge with collaborative design support. Reliable magnetics don't just move current—they move your project forward.

Ready to optimize your next transformer design with the right core material?

Contact us today for expert guidance on your custom magnetic components.

Your product design hits a roadblock. The perfect magnetic component doesn't exist—at least, not off the shelf. For engineers and product designers, this challenge is all too familiar. Selecting the wrong magnetic components can lead to performance issues and additional cost that can affect your bottom line.

As North American manufacturing grows again, companies must find new ways to compete with offshore pricing pressure. The pressure to innovate faster while reducing costs forces difficult trade-offs. Engineers often find themselves choosing between design compromises, extended timelines, or budget overruns. This balancing act becomes even more challenging when standard components fall short of performance requirements.

Time and cost matter more than ever in product development. Companies need to make smaller, better products faster while staying profitable. This is where custom magnetic components can give your product a real edge in the market. Choosing between custom and standard magnetic parts affects everything—from how you design to how customers use your product.

Product development cycles move faster today, so each design choice matters more. When you work with custom magnetic component makers, you get expert help that makes your designs better from the start. This teamwork transforms what could be just a components decision into a strategic advantage for your product's future. Engineers who understand this partnership gain more reliable products, superior performance, and greater market longevity.

Engineers often pick standard parts to save money upfront. This makes sense during early budgeting. But this approach can force design changes that cost more in the end. Getting standard catalog parts can also be tricky.

Supply chains for off-the-shelf parts can be unpredictable, causing surprise delays. These delays can throw off your product schedule and slow down your market launch.

Standard components rarely fit perfectly in your unique design. When engineers are required to fit “square components into round holes”, they are often forced to:

Redesign circuit boards for larger component footprints

Add cooling solutions for parts that run too hot

Install extra shielding to block electromagnetic interference

Create special brackets or mounts

These changes waste time and money, and they add to the overall complexity of the PCB (Printed Circuit Board) or cabinet design.

Using standard magnetic components that aren't finely tuned to your specific needs may result in energy waste in addition to thermal and reliability issues.

Efficiency is always a design consideration in any application; even small percentage improvements can make a significant difference. In power-hungry products like industrial equipment or electric vehicles, efficiency gaps translate directly to energy costs over the product's lifetime. Custom designs convert energy more efficiently, improving system reliability and operational costs.

Custom magnetic compone nts are built to match your exact size needs and packaging limits. Custom connection points make assembly easier and more durable, cutting production time and warranty claims.

With today's push for smaller products, space really matters. Custom transformers and inductors can be sized just right for your needs, often smaller than standard options. This gives your product an edge through better use of space.

Custom transformers and inductors are designed to meet your exact voltage, current, and frequency requirements. A custom design will create optimal power transfer ratios, impedance matching, and frequency response for your specific application.

Custom magnetic components deliver only the electrical performance your application needs—no more, no less.

Duty cycle refers to how long a component remains active within each operating cycle, typically expressed as a percentage. A 60% duty cycle means the part is in operation 60% of the time and idle the other 40%. In magnetic components, a larger duty cycle generates more heat and increases electrical stress—especially in high-current or fast-switching environments.

This is where standard components can struggle. They’re not built around your specific operating profile or thermal requirements. Custom inductors and transformers from Electronic Craftsmen are engineered for your exact duty cycle—reducing core losses, managing heat more effectively, and improving long-term reliability under real-world conditions.

When you work with custom magnetic component makers, you get valuable design expertise and material advice. These expert engineers can suggest solutions you might not have thought of.

Partnering with skilled engineers ensures better performance and reliability. Many custom manufacturers also offer quick prototyping and testing, which reduces risks and gets your product to market faster.

Custom magnetic components offer another big advantage: they can adapt as your needs change. As your product evolves, custom manufacturers can adjust specs step by step without starting over. This flexibility helps when:

Requirements change: custom designs can sometimes be tweaked using the same materials to meet new requirements.

Markets demand higher efficiency or smaller sizes: With a custom collaborator, there may be opportunity for design changes that do not affect the entire assembly.

New technologies create chances for performance improvements within the same package size

With standard components, these changes often mean starting from scratch. Custom magnetic solutions let you build on what you've already done, saving your engineering work across product generations.

MRI machines, surgical tools, and diagnostic imaging equipment require quality components to function reliably.

In medical devices, reliability isn't just about convenience—it can be life or death. Custom transformers provide the stable, clean power that sensitive medical equipment needs, with backup features built specifically for healthcare settings.

The aerospace industry faces tough weight and space limitations that require compact, high-efficiency transformers. Components must also work in extreme temperatures, vibration, and radiation.

In aerospace, lighter and more efficient parts mean less fuel used and longer missions. Custom magnetics can meet the strict quality standards that aerospace and defense require.

Wind turbines and solar panels need high-efficiency inductors and transformers to handle changing power loads. The unpredictable nature of renewable energy creates unique challenges that standard parts struggle with.

Custom magnetic solutions improve power conversion and energy storage. In renewable energy, even small efficiency gains can greatly impact whether a project makes financial sense over its 20–30-year life.

Motors, sensors, and controllers in factories need precise power regulation. Custom magnetics provide the reliability needed in noisy and tough factory settings.

The harsh conditions of 24/7 manufacturing push components to their limits. Custom magnetics designed for these demanding environments help production lines avoid costly downtime while making equipment last longer.

EVs need high-efficiency power electronics to maximize battery life and range. Custom transformers and inductors improve both charging systems and onboard power conversion.

Even small improvements in power conversion efficiency lead to better driving range and faster charging—key factors in EV buyer satisfaction. As EV technology changes rapidly, custom magnetic components can be updated to support new battery technologies and charging standards.

Think of custom magnetic components as an investment in your product's performance and lifespan, not just an expense. Here's why common concerns shouldn't hold you back:

Initial Cost vs. Total Value: While custom components may cost more upfront, they eliminate the need for workarounds and additional parts. This can actually reduce overall system costs when considering simplified assembly, streamlined testing, and improved reliability in the field.

Production Timeline: Modern custom manufacturers have streamlined their processes to compete with off-the-shelf timing. Many offer rapid prototyping that helps prevent costly redesign cycles and delays. With the right partner, custom magnetic components can often be delivered quickly enough to keep your project on schedule.

Design Process: Clear specs and teamwork make customization straightforward. Most engineers find that the time spent defining requirements saves trouble later by avoiding the problems that come from forcing standard parts to fit non-standard uses. Starting with a thorough design discussion helps identify potential issues before they become costly problems.

Minimum Order Quantities: Worried about being forced to order large quantities? Many custom manufacturers now offer flexible production options. They understand that new products often start with smaller production runs before scaling up and will work with you to find the right balance of cost efficiency and order size.

Choosing between standard and custom components isn't just about cost. It's about making products that perform their best in tough markets.

Custom magnetic components offer form, function, and benefits that prevent hidden costs and reliability problems. This is why industry leaders in medical technology, aerospace, renewable energy, and industrial automation use custom solutions to gain an edge.

Working with expert engineers ensures the best design choices for your specific needs. In today's challenging manufacturing world, these advantages can make the difference between a product that just works and one that truly stands out.

Ready to give your product an edge? Contact us today for help with your specific application. Our team of experienced engineers will help you find the perfect magnetic solution for your next product innovation.