We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

In late December 2017, a customer advised us that he had some legacy GE power supplies that were failing. They brought us some samples of an epoxy-sealed transformer that they believed to be the source of the problem. While the customer was a well-recognised Electronic Reverse Engineering & Industrial Electronic Repair firm, they had no information about the transformer’s design and were eager for a solution.

“Do you think you can help us?” he said. “We are hearing of more and more of these that need repairing (another 15 units today)”

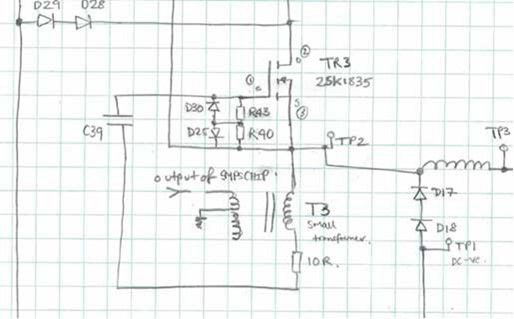

After some initial discussion and planning, the customer traced the layout of the circuit board and prepared a sketched schematic. He also took some inductance measurements and screenshots of scope traces measured across the coil between ground and (though components) to the output of the SMPS chip. From this, we were able to confirm that the device was a “Gate Drive Transformer”. These devices are used to couple gate-drive circuits to MOSFETs and IGBTs operating at switching frequencies. The purpose is to modify the voltage level to the gate, provide impedance matching, and to provide voltage isolation.

There was limited room on the circuit board for a replacement part. To develop a new design, it was crucial to determine the wire size and turns ratio. Because we had no idea what was inside the sample, the epoxy containing the part was dissolved to see the failed transformer. After tearing down the part, we were able to develop an entirely new design based on the measured electrical parameters and physical characteristics that were revealed. The customer was able to provide the circuit board pinouts. Formerly constructed on a toroidal core, our new design would employ an EFD20 platform using 3F3 core material. The gate side of the transformer utilized triple-insulated TEX-E magnet wire. Based on our experience, we determined that this transformer did not need to be epoxy-molded and needed only air-dry varnish to encapsulate the part to reduce cost. A sample of the bobbin was sent to the customer who confirmed that the part would physically fit on the circuit board.

|

The customer ordered 10 prototypes on January 25. A full prototype evaluation was undertaken by the Design Engineer and the Quality Manager prior to shipping the parts on Feb 1. On Feb 27, the customer advised, “... good news. The transformers work and are in the field running well. We would like to order 50 of these...” |

Our customers frequently ask Electronic Craftsmen to help solve problems with legacy parts that fail. This is a great example demonstrating our ability to quickly troubleshoot issues, and design and deliver a replacement prototype, before placing a production order. This project took two months from start to finish.