We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

In aerospace, there’s no room for guesswork. Every component—no matter how small—must meet the highest standards. That’s why AS9100 exists. It’s the gold standard for quality management in aerospace manufacturing, created to ensure parts are built with precision, tested for reliability, and fully traceable at every step.

However, this certification isn’t just for planes and satellites. The same systems that keep aircraft safe are now guiding how many teams build parts for energy, medical, defense, and communications. And for components like transformers, inductors, and magnetic assemblies—where performance depends on exact design and materials—that kind of structure makes a real difference.

This post breaks down what AS9100 certification really involves, how it applies to magnetics, and why working with an AS9100-certified manufacturer is a smart move—even if you’re not building for aerospace. Whether your system operates at high altitudes or deep in a control cabinet, quality still matters.

AS9100 is a quality management standard created specifically for aerospace and defense. It’s built on ISO 9001 but adds deeper requirements that reflect the complex needs of flight systems. For custom magnetics manufacturers, it means every step of the process—from design to testing—is held to some of the highest standards in the industry.

AS9100 covers areas like:

Full traceability of materials

Detailed documentation for every step

Risk-based decision-making during development

Strict testing and verification processes

Oversight of suppliers to prevent issues with quality or counterfeits

Getting certified isn’t easy. It involves a full audit by an accredited body, along with proof that processes are stable and consistent. Not all manufacturers meet these standards.

Once certified, companies don’t stop there. AS9100 requires yearly audits and full recertification every three years. That ongoing process helps ensure manufacturers stay focused on improvement—not just passing a one-time check.

Magnetics often fly under the radar—until something goes wrong. But components like transformers and inductors are critical in nearly every system that depends on clean, stable power. When these parts fail, the results can be serious.

In aerospace, even a small shift in performance can affect everything from flight control to communication. Magnetic components must survive vibration, extreme temperatures, and sometimes radiation, all while maintaining their exact performance specs.

That’s where AS9100 makes a difference. Certified manufacturers follow strict design and process controls that help catch problems early. This includes things like:

Environmental and stress testing

Design verification at each stage

Process controls for winding, potting, and soldering

Full performance testing for every build

The result is better consistency, fewer unexpected issues, and higher confidence that each part will perform as designed. And while these benefits are critical in aerospace, they also help across industries where failure isn’t an option.

Many industries face the same performance challenges as aerospace—just in different forms. That’s why AS9100 certified magnetics are gaining traction in other high-reliability fields:

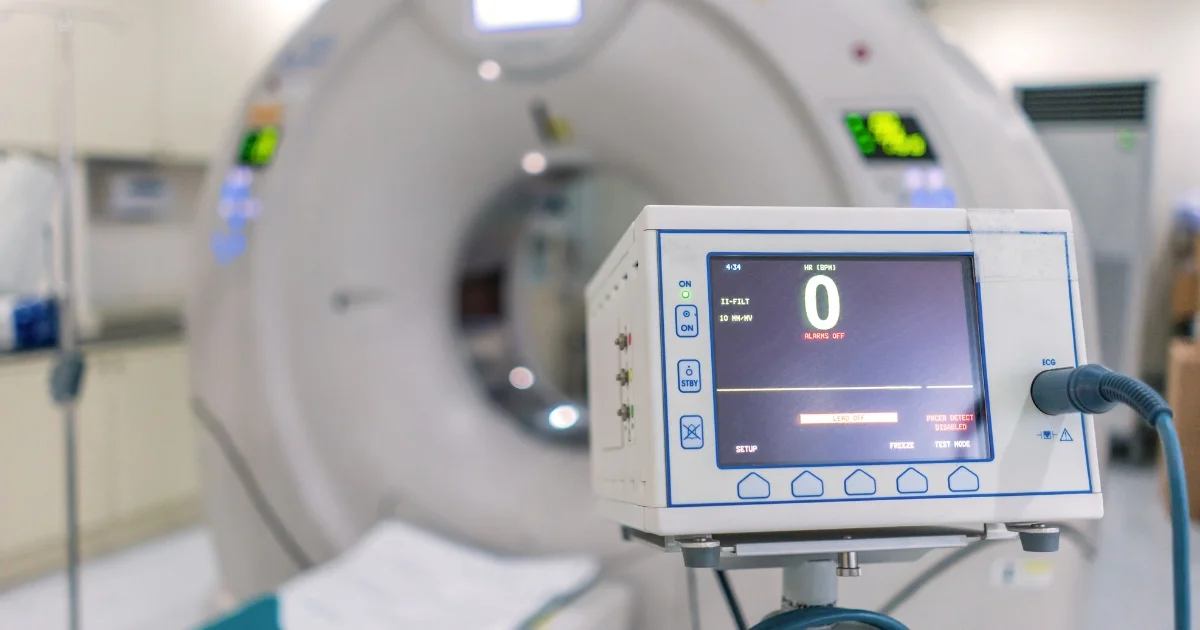

Systems like MRI machines, patient monitors, and diagnostic tools need components that are stable and trustworthy. Transformers and inductors designed under AS9100 can support these requirements with proven reliability and traceability.

Military communications and field systems operate in tough conditions. The quality controls required by AS9100 help ensure that magnetic parts can handle vibration, temperature shifts, and long-term use without failure.

Solar and wind equipment often runs for years with little downtime. Components built under AS9100 guidelines bring long-term durability to converters, inverters, and control systems exposed to outdoor conditions.

High-vibration environments like trains or factory floors place stress on every part. Magnetics built under AS9100-certified processes are designed to meet those demands.

Uptime is critical in networks and signal systems. Components built to strict standards—like those required in aerospace—can help reduce maintenance and improve system availability.

Working with a certified manufacturer gives OEMs and engineers:

More predictable performance

Clear documentation for compliance or traceability

Less risk of production issues or late-stage changes

Easier onboarding into regulated environments

Whether the end system flies or not, AS9100 certified magnetics help build stability into complex designs—and that matters everywhere.

AS9100 certification isn’t just a label—it reflects a full quality system that affects how a manufacturer works at every level.

Reviewing current processes through a gap analysis

Developing updated procedures and documentation to meet AS9100 standards

Implementing quality systems across all operations

Completing a pre-assessment to identify any weak points

Undergoing a formal certification audit by an accredited third-party organization

Yearly surveillance audits to review key processes

Internal audits to ensure continuous alignment with the standard

Management reviews to track system performance

Documented corrective actions for any issues found

Full recertification every three years to maintain the certification

For transformer and inductor manufacturing, certification adds an extra layer of discipline. It includes:

Verifying and tracking all materials used

Validating key steps like winding and impregnation

Running environmental tests that match real-world use

Monitoring critical performance metrics through process control

Keeping detailed records of every design, procedure, and test result

This commitment to quality continues throughout the product’s life—from design and production to final delivery and field use. The system helps reduce risk at every stage, supporting things like counterfeit part prevention, failure tracking, and using customer feedback to improve over time.

Many manufacturers hold ISO9001 certification, which shows they follow basic quality management practices. It’s a solid foundation, but AS9100 takes things further—especially for industries that demand high reliability, like aerospace or advanced electronics.

General quality management system requirements

A process-based approach to production

Customer satisfaction and feedback

Continuous improvement practices

Detailed regulatory compliance and documentation

Strong risk management throughout the product lifecycle

Emphasis on product safety and key feature identification

Configuration and change management controls

Tighter process validation and operational discipline

You can think of AS9100 as ISO9001 designed for mission-critical environments. These extra requirements aren’t just formalities—they help address real-world challenges where a single failure can cause major problems.

For custom magnetics manufacturers, AS9100 leads to stronger design systems, better process control, and more complete testing. That means more dependable components, whether they end up in aerospace or anywhere else performance matters.

Not all AS9100 certified manufacturers operate the same way. For teams sourcing high-reliability magnetics, it’s not just about earning the certification—it’s about how well those quality practices are built into everyday production.

A good partner will have in-house capabilities for key steps like winding, potting, encapsulation, and testing. These operations directly affect how magnetic components behave—especially in demanding systems where temperature, voltage, or size constraints come into play.

Electronic Craftsmen, for example, supports multiple winding formats, including toroidal and rectangular winding. This flexibility makes them a strong fit for both compact layouts and high-current designs.

It’s also worth asking whether the manufacturer provides custom magnetics, not just catalogue parts. Complex systems often need transformers or inductors tuned to specific power levels, frequencies, or mechanical constraints. Partners that offer design support, prototyping, and simulation tools can help ensure the magnetic components work exactly as intended within your larger system.

For harsh or high-risk environments, advanced testing capabilities are essential. Thermal cycling, and partial discharge detection (Corona), help validate that components will perform as expected—not just in lab conditions, but in the field over time.

Ultimately, selecting the right magnetics partner means finding a team that brings more than compliance. It’s about working with engineers who understand your application, build for long-term consistency, and have the tools to support precision at every step of the process.

AS9100 certification is more than a formality—it reflects a manufacturer’s full commitment to quality across design, production, and testing. For magnetic components, that means tighter controls, deeper documentation, and higher confidence in performance, especially when failure isn't an option.

Working with an AS9100 certified magnetics manufacturer gives you more than a finished part. It gives you visibility into the process behind that part—how it was designed, built, and verified to perform as expected. That kind of process discipline leads to better outcomes, whether you're developing systems for aerospace, energy, defense, or industrial applications.

The value of AS9100 doesn't end with compliance. It supports long-term reliability, smoother onboarding for regulated projects, and fewer surprises during testing or integration. The same principles that keep aircraft systems running safely help reduce risk in every environment.

If your application demands performance under pressure—whether in the air, on the ground, or in mission-critical systems—partnering with an AS9100 certified manufacturer gives you more than peace of mind. It gives you a clear advantage: proven process control, documented reliability, and components built to meet tight specs without cutting corners.

Choosing a partner like Electronic Craftsmen means building with confidence from the start. Because when failure isn’t an option, neither is guesswork.