We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Not all transformer core material performs the same, and the wrong choice can compromise your magnetics design. Core material affects how a transformer performs under load, how hot it gets, how much space it occupies, and even how much it costs to build and run.

While windings and insulation often get the spotlight, the core is doing the heavy lifting behind the scenes. It handles the magnetic energy flow, and the way it does that depends entirely on the material you choose.

This post looks at why transformer core material matters. You'll see how it impacts efficiency, size, and cost—and how the right expertise can help you pick the optimal material from the start.

At the heart of every transformer is the core. It's responsible for the transfer of magnetic energy through the magnetic device. The better the material at handling this transfer of power, the more efficient the device operates.

Every core material behaves differently. Some materials are better at high frequency switching than others (i.e. ferrite). Each one comes with its own limitations and drawbacks as it pertains to heat rise, signal distortion, and energy loss.

When the core material precisely matches the application, everything works better. As efficiency increases, losses go down. Size and weight are easier to control but when the material isn't a good fit, systems can run hot, lose power, or require larger parts to hit the same performance levels.

That’s why engineers spend time on magnetic core selection early in the design process—it’s one of the most critical choices in magnetic components.

Core material has a direct effect on how much energy your transformer uses—and how much it wastes. As current moves through the transformer, part of it turns into heat. Some materials hold that loss a minimum…others don't.

Ferrite, for example, performs well at high-frequencies and keeps energy losses low. Silicon steel is more rugged and works better at low frequencies, though it loses more power to heat. Powdered iron sits somewhere in the middle, offering balance between performance and strength.

Access to thermal modelling and performance testing early in the design process helps teams choose materials that keep losses low without risking overheating.

Core losses happen in two main ways: hysteresis loss and eddy current loss. Hysteresis loss occurs as the magnetic field repeatedly changes direction, creating friction at the molecular level. Eddy current losses happen when small electrical currents form within the core material itself.

Different materials combat these losses in different ways:

Silicon steel uses thin laminations to break up eddy currents

Ferrite naturally resists eddy currents with high electrical resistance

Powdered iron uses tiny, insulated particles to minimize both loss types

Nanocrystalline cores offer exceptional performance but at higher cost

Matching these properties to your specific frequency and operational range and duty cycle is crucial. But isn't a high-performing core always better? Not necessarily. Some applications might not justify the cost of premium materials if the efficiency gains aren't critical to the design requirements.

Different materials handle magnetic energy in different ways. That affects how large your magnetics need to be. Some high-performance materials allow for smaller core shapes because they hold more energy in less space. That's why ferrite and high-flux cores are common in aerospace and electric vehicle systems, where every gram matters.

In certain instances, size might be less critical, so designers might choose more affordable but heavier materials like laminated steel.

Material costs vary. Some are more expensive to shape. Others are harder to find. The right choice depends on your budget, timeline, and performance needs. Ferrite may cost more upfront, especially for custom shapes. But it can also reduce long-term energy loss and system heat.

Powdered cores are often easier to source and machine. Laminated steel is cost-effective for basic low frequency uses but less efficient over time. Working with vendors that offer a range of options helps teams avoid long delays or overspending on overbuilt designs.

The perfect core isn't just about electrical performance—it needs to physically survive its operating environment. Some materials offer excellent magnetic properties but poor mechanical strength.

Core materials must withstand:

Mechanical vibration and shock

Thermal cycling and expansion

Installation stress during winding and assembly

Environmental factors like humidity and corrosion

Ferrite is often recommended for high-frequency applications where electromagnetic interference (EMI) is a concern. But when mechanical durability matters more, encapsulated powdered iron cores can handle rougher conditions without cracking.

Precision machining helps teams meet tight specifications without overbuilding. This is particularly valuable for ferrite cores, where small adjustments to the physical dimensions can dial in exact inductance values without compromising performance.

Every industry comes with its own design constraints—and each one depends on the right core material to meet performance, safety, and cost goals. At Electronic Craftsmen, we support a wide range of applications, from aerospace to automation. Explore the industries we serve.

In aerospace systems, size, weight, and reliability are everything. Transformers often need to perform under high-vibration conditions and within tight thermal limits. That means using materials like ferrite, which can support high frequency switching in a compact footprint. Additionally, Electronic Craftsmen offers In-house ferrite grinding so designers can precisely meet stringent component requirements.

Lastly, our transformers are constructed to meet the requirements of standards such as MIL-PRF-27 for added reliability in demanding conditions.

In communications gear and high-frequency power systems, signal clarity and thermal stability are key. That's where ferrites and powdered iron cores often shine. These materials support faster switching speeds with fewer electromagnetic losses.

For low frequency applications such as in industrial and automation systems, Laminated steel magnetics are widely used. However, these components may be subject to environmental challenges such as high humidity, extreme temperatures, and industrial contaminates. Features like vacuum encapsulation, antifungal coatings, and epoxy coatings protect core materials in extreme conditions.

Transformer cores in renewable energy systems face unique challenges. Solar inverters, wind power generators, and energy storage setups all demand high efficiency core materials to make the most of limited energy capture—often while operating outdoors or in variable conditions.

For solar inverters, the core must support frequent load changes as sunlight shifts throughout the day. This dynamic environment favours materials with low hysteresis loss that can maintain performance across thousands of magnetic cycles. Ferrite and amorphous cores often fit the bill, offering solid efficiency at a reasonable cost.

Wind power adds another layer of complexity. These systems operate at variable frequencies and can face mechanical vibration that stresses brittle core materials. Cores need to handle that strain while staying efficient across changing electrical loads.

In EV charging and battery storage, transformers often use nanocrystalline or powdered metal cores. These materials support high-frequency switching while keeping transformer size compact—a key factor in modern power systems.

Thermal management is especially important in green tech, where transformers may be enclosed with limited cooling. Core materials that naturally run cooler help maintain efficiency in hot weather and extend system life.

We design custom magnetics for renewable energy with a focus on efficiency, temperature stability, and long-term reliability—helping your systems produce maximum power with minimum waste.

Choosing the right core material isn't just about specs—it's about solving a system-level challenge. That's where specialized magnetics manufacturers make the biggest impact.

Instead of guessing which material will work, you need hands-on support with electrical modeling, thermal simulations, and prototype testing. These tools help compare options based on actual performance, not just datasheets.

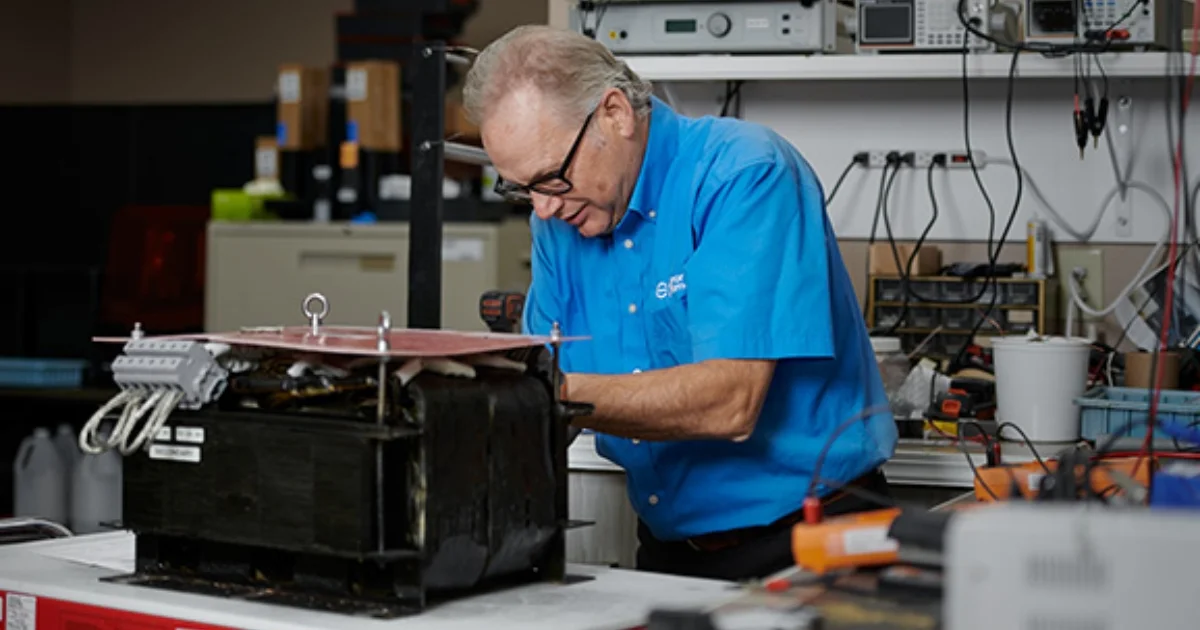

At Electronic Craftsmen, we offer in-house ferrite core grinding. That means parts can be built to tight inductance specs without needing a full layout change. This is especially useful when space is limited or when weight must be minimized without losing performance.

With both domestic and offshore vendor relationships, we source a wide range of materials—while still doing final testing and assembly in Canada to ensure quality. Whether your goal is cutting size, improving efficiency, or staying within budget, our team helps you design with the right material from the start.

Choosing the right core material doesn't just fine-tune your transformer—it shapes your system's future. From thermal losses and switching frequency to footprint and compliance, the core plays a central role in performance and cost.

That's why teams across aerospace, green energy, and industrial automation trust Electronic Craftsmen to help them make the right call—combining deep material knowledge with collaborative design support. Reliable magnetics don't just move current—they move your project forward.

Ready to optimize your next transformer design with the right core material?

Contact us today for expert guidance on your custom magnetic components.