We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

We build custom applications for many industries including the ones with tough, demanding Aviation and Marine environments. We know special consideration must be given to vibration, moisture, weight, contamination and qualification. Unique winding configurations, high-efficiency cores, high-strength and non-nutrient encapsulants.

That's why we work collaboratively with you and your technical personnel to to develop the optimal solution for your complex requirement.

Example Types of Aviation & 400Hz Inductors & Chokes:

Recent Work

3 Phase DC Differential Mode Power Inductor (Aviation Power)

This custom three-phase DC power inductor is used in the Auxiliary Power Unit in a commercial aviation platform. 50uH, 125A/ph, 15kHz Tape-Wound E-Core, 0.010 Copper Foil Windings, High-Temperature Teflon Leads, Class H (220C) insulation. Insulation resistance, 40Mohm (min) @ 500Vdc. Manufactured in Canada.

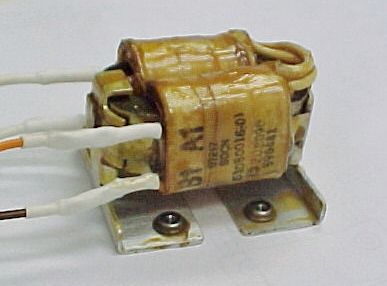

Coupled Inductor

2.0mH, 18A, 15 KHz Tape-Wound Amorphous Alloy C-Cores, Specialty Brackets, Teflon Leads

Encapsulated Toroidal inductor

2mH, 1A, 400Hz High Flux Powder Cores, Epoxy Cast, Threaded Standoff for Mounting

Aviation and 400Hz Inductors and Chokes Capabilities at Electronic Craftsmen

Inductance: uH to H

Currents to 1100A nominal, AC or DC

AC Ripple Current and Harmonics accommodated to specification

Working Voltage up to 12kV (depending on frequency); multiple stages possible for higher outputs

Frequency: 25Hz to 1200Hz (typical)

Temperature Class to 220C (155C / Class F typical)

Weight: 0.06 oz / 1g to 550 lbs / 250kg

Multiple taps as required

Dielectric Strength (hipot) to 30kVac or 20kVdc

Parts can be vacuum varnished or molded with a variety of hard or soft encapsulant materials with thermal conductivity.

Wire sizes from 1-45 AWG or Copper Foil to 0.050in thick (in multiple layers for higher current); Litz wire for higher frequency

Regulation to specification

Manufactured using all known state-of-the-art magnetic core materials, including but not limited to electrical grade steel laminations, ferrites & powdered iron, nickel-iron alloy, iron amorphous metal strip-wound cores, nanocrystalline cores and small toroids.

Antifungal and non-nutrient coatings available

Corrosion resistant coatings & platings available

Standard or custom terminations & leads

Mounting Configurations: pcb-mount (horizontal or vertical), custom or standard brackets or stacked configurations

Designed to meet CSA & UL (safety) or MIL PRF 27 (aerospace / military) requirements upon request

MIL PRF 27 Grade 5 & 6 encapsulation available

On the ground, in the air or on the water. Contact us with your requirements.