We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Highly engineered products developed to meet complex customer specifications. Materials and methods are uniquely selected to maximize performance and reduce costs. We work collaboratively with you to create optimal solutions to demanding requirements.

Example Types of Specialty Transformers:

* Note: Almost any magnetic component can be Grade 5 molded (sealed). We use a wide selection of 2-part epoxy, RTV and/or other silicone materials.

Recent Work

.jpg)

Toroidal Water Cooled Transformer Assembly (EC Custom Model 210033)

Customer design, assembled at Electronic Craftsmen. Used in an Induction Heating application.

Multiple windings of 2625/44 Litz wire assembled onto 2 x 4.21"OD 3F3 Ferrite cores together with multiple sets of connection and water-cooling hardware assemblies. 4200Vdc hipot.

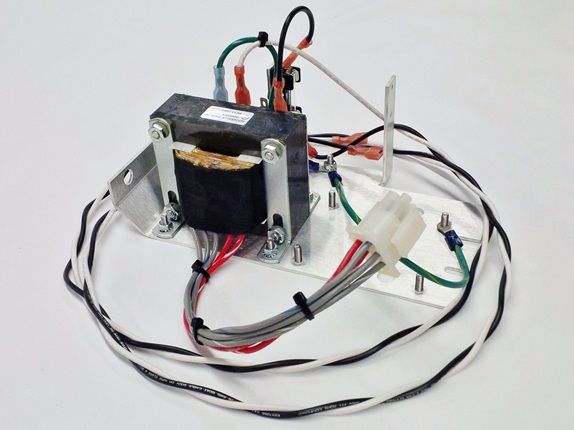

Power Step-Down Transformer Assembly with Wiring Harness and Integral Output Protection

Value-added custom step-down transformer assembly for laboratory equipment. Transformer incorporates a multi-tapped input (100/120/200/220

/230/240V) for international supply applications and dual SELV outputs, 22VA @ 50/60Hz. Includes wiring harness and output fuse protection circuitry mounted together with the transformer on a conversion coated aluminum bracket. RoHS compliant. Custom Model 206053.

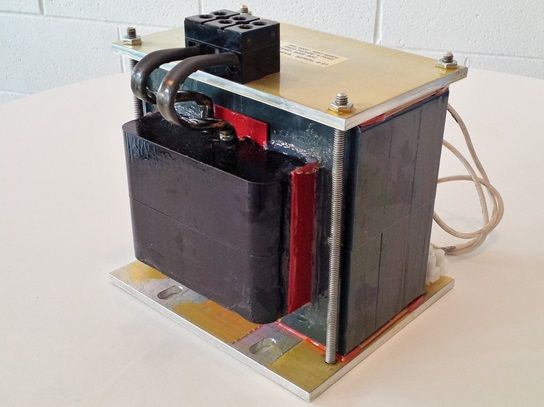

High Voltage Transformer, 6000V @ 20kVA, 4-7kHz with Epoxy Encapsulated Windings for Corona Resistance

This custom specialty transformer was designed for use in a system for ozone generation for water sanitizing. This transformer utilizes epoxy-encapsulated windings to provide additional protection against damage caused by partial discharge (corona). Encapsulation is performed under vacuum with the goal of replacing air with epoxy to provide a superior medium of insulation. Rated 600V input, 6kV output @ 4-7kHz. Insulation is Class F (180C). Copper foil and Litz wire windings on a gapped ferrite core. Model 211020.

We design and manufacture custom components that will solve your most difficult performance challenges.

Specialty Transformer Capabilities at Electronic Craftsmen

Power: From mW to 50kVA @ 60Hz or up to 200kVA @ 20kHz (typical)

Working Voltage up to 12kV (depending on frequency); multiple stages possible for higher outputs

Frequency: 25Hz to 500kHz (typical)

Temperature Class to 220C (155C / Class F typical)

Weight: 0.06 oz / 1g to 550 lbs / 250kg

Multiple taps as required

Dielectric Strength (hipot) to 30kVac or 20kVdc

Parts can be vacuum varnished or molded with a variety of hard or soft encapsulant materials with thermal conductivity.

Wire sizes from 1-45 AWG or Copper Foil to 0.050in thick (in multiple layers for higher current); Litz wire for higher frequency

Regulation to specification