We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

So are our solutions.

We are Electronic Craftsmen Corporation, your custom magnetics solutions partner since 1956.

We are Electronic Craftsmen Corporation, your custom magnetics solutions partner since 1956.

We are known for our innovation and high-quality specialty transformers, inductors, and other custom parts for power electronics applications. We service diverse industries, including aerospace, communications, and green technologies, collaborating closely with customers in Waterloo Region and beyond. We supply and deliver superior custom magnetics solutions for evolving technological challenges.

Electronic Craftsmen Corporation is an AS9100 & ISO9001 Registered company.

Our team loves a design challenge. We can provide custom-made products that conform to most market specifications, including the ability to replicate a wide range of catalogue items. Our design database includes more than 10,000 products to date.

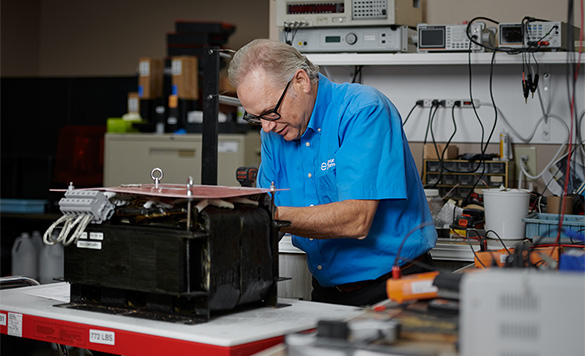

From encapsulation processes, in house ferrite grinding, winding, coil assembly, and more, we create exciting custom products and solutions for our clients across various industries, right here in our plant.

Explore our full range of services below.

"Satisfying demanding environmental and electrical requirements"

Processes.jpg)

"Flexibility and versatility to quickly meet critical inductance specifications."

Tolerances to 0.001in

Unlimited applications including flyback transformers, step-gap transformers and inductor gaps

Eliminates time and cost of sending out to external sources or purchasing standard gapped cores

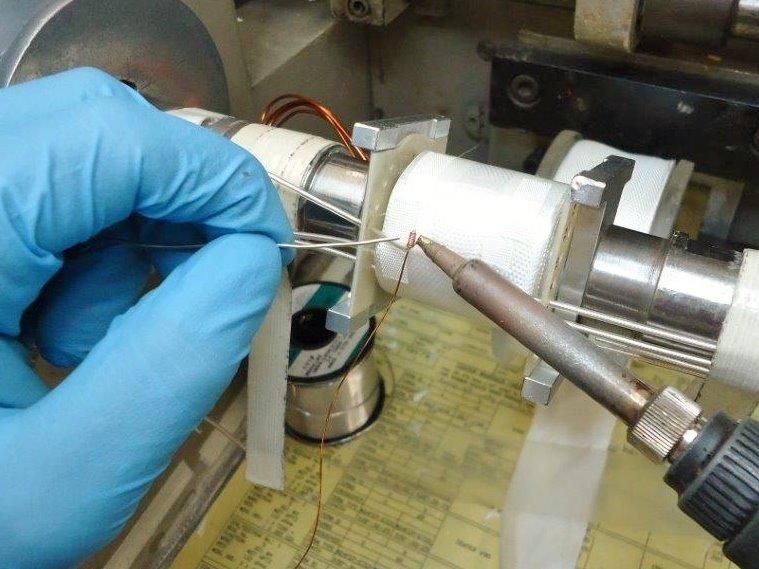

"Our operators are trained to execute J-STD-001 soldering operations"

Detailed standard practices and work instructions

RoHS or Leaded solders

High current brazing

"Reduced cycle time on prototyping and custom-designed mechanical assemblies."

In-house fabrication of custom inspection fixtures and production tooling

Development of custom molds for encapsulation

Short runs of brackets, terminals and other custom materials for fast production of prototype

"State-of-the-art Voltech transformer testers provide a fast, reliable and flexible test solution."

Tolerances to .05%

Unlimited testing capabilities for transformers.

"Advanced testing capability to verify performance under extreme environmental conditions."

8 cu. ft. with hot-cold and humidity cycling

Range from -73C to +190C

Cascading cooling compressors with LN2 boost for accelerated performance

Dual plotting for both temperature and humidity

"Advanced PC based, AC Partial Discharge test set"

0-20KVac @ 100mA, 60Hz

Detects partial discharge up to 2 pC

Chamber Size: 17”W x 30”D x 30”H (8.85 cu ft)

Omicron MPD500 Digital Detector

Bench top winding machines (Ruff GmbH) for high precision linear winding applications

CNC controlled traverse, electronically controlled for precise control of tension for guaranteed repeatability

Pitch accuracy of 0.00004”

Electronically stored winding programs

Perfect-layer coils, self-supported coils and edge wound coils

"Custom Magnetics require flexibility in Winding"

Bobbin Winding

Toroid Winding

Stick Winding

Unit Winding

Layer Supported Winding

Operator Guided Winding

Heavy Winding including rectangular wire and Foil to 22” wide

Our approach to utilizing partner vendors is centered on transparency and convenience for our customers. Typically, all production parts undergo rigorous testing at our Waterloo, Ontario facility before delivery to ensure 100% conformance. However, when it makes sense for higher volumes and cost reduction, we have established, longstanding relationships with trusted vendors in China, Taiwan, and India. These partnerships, some spanning over a decade, allow us to select the most suitable manufacturer based on part parameters. While we prioritize quality and visibility, we can also facilitate direct drop-shipment to customers' off-shore facilities when necessary, although this may involve additional quality assurance measures.